The modular sliding track system is an efficient solution designed by YZ DITECH specifically for stage machinery, dynamic exhibition displays, and film special effects scenes. This system consists of three parts: the Power Trolley, the Slave Trolley, and Customized Track. It deeply integrates an intelligent control system to achieve high-precision positioning and synchronized control of multiple Power Trolleys. The system employs an electromechanical design, featuring high precision, high reliability, low noise, and easy installation, making it suitable for various complex application scenarios.

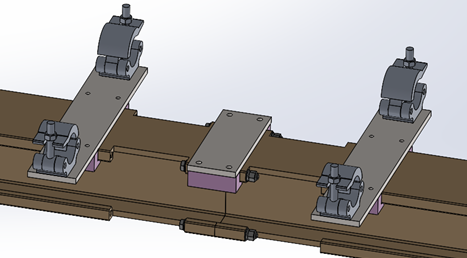

Customized Track Key Function

To facilitate transportation and elevator access, the standard length is 2 meters per section. Optional lengths include 1 meter and 3 meters.

The track load capacity is 600kg/m, with a safety factor of over 2 times.

The selected track body has a self-weight of 19kg/m, reducing weight for easier transport and installation.

Considering the usage scenario involves a modular setup, gear transmission is used between the track and the trolley’s gears.

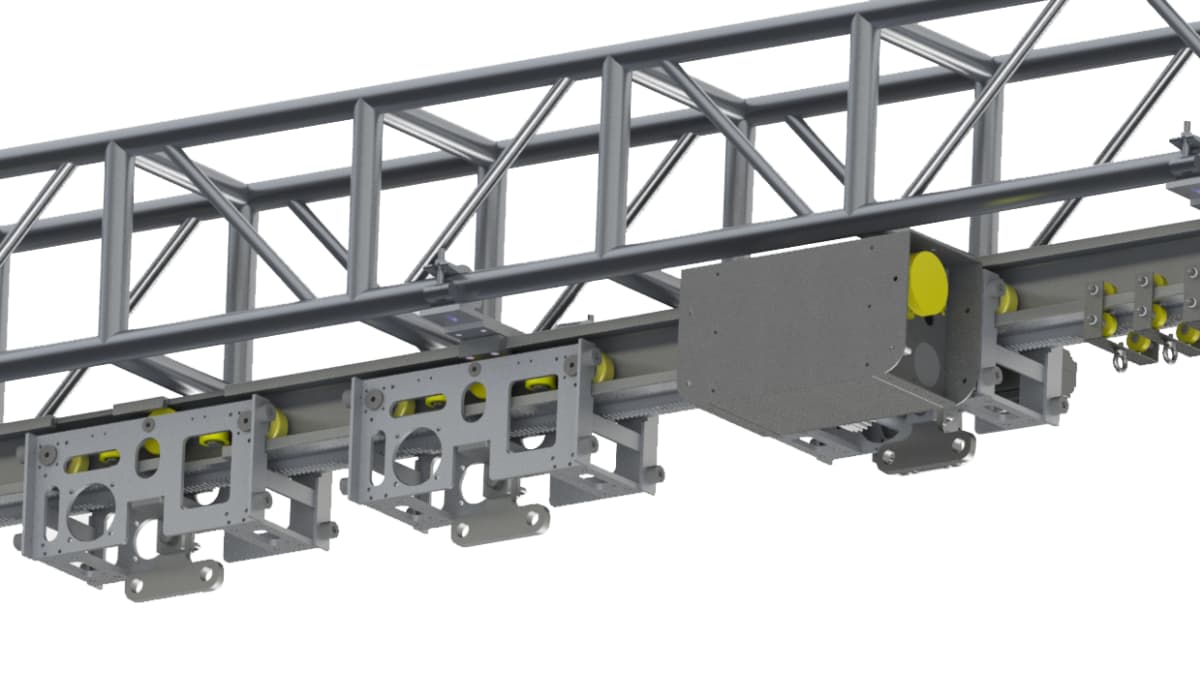

Track connections are convenient and straightforward, stable and reliable. Screws and pressure blocks are used to connect the tracks, while lighting hooks are used for connecting tracks to trusses. The connection points for the lighting hooks can be adjusted forward and backward on the track to avoid interference from the truss side pipes. The default track connection plate is 400x400 truss, with other sizes available as options.

For aerial tracks with a total length of less than ten meters, wiring can be done using a tensioned steel wire rope to hang curtains. For aerial tracks longer than ten meters, the steel wire rope will sag significantly in the middle, requiring a structural profile to hang curtains for wiring.

The lighting hooks used for connecting the track to the truss are TUV certified, with each hook rated for a load of 750kg.

The track load is related to the span of the hanging points, as shown in the table below (with a safety factor of 2 times):

|

Hanging Point Span(m) Load Capacity (kg) |

|

|

|

|

1.5m |

1200 |

1200 |

1200 |

|

3m |

400 |

650 |

1000 |

|

4m |

225 |

300 |

500 |

Installation of Track

Hanging Installation

Ground Dual-Spec Installation