The Intelligent Core of Black Warrior Stage Automation System

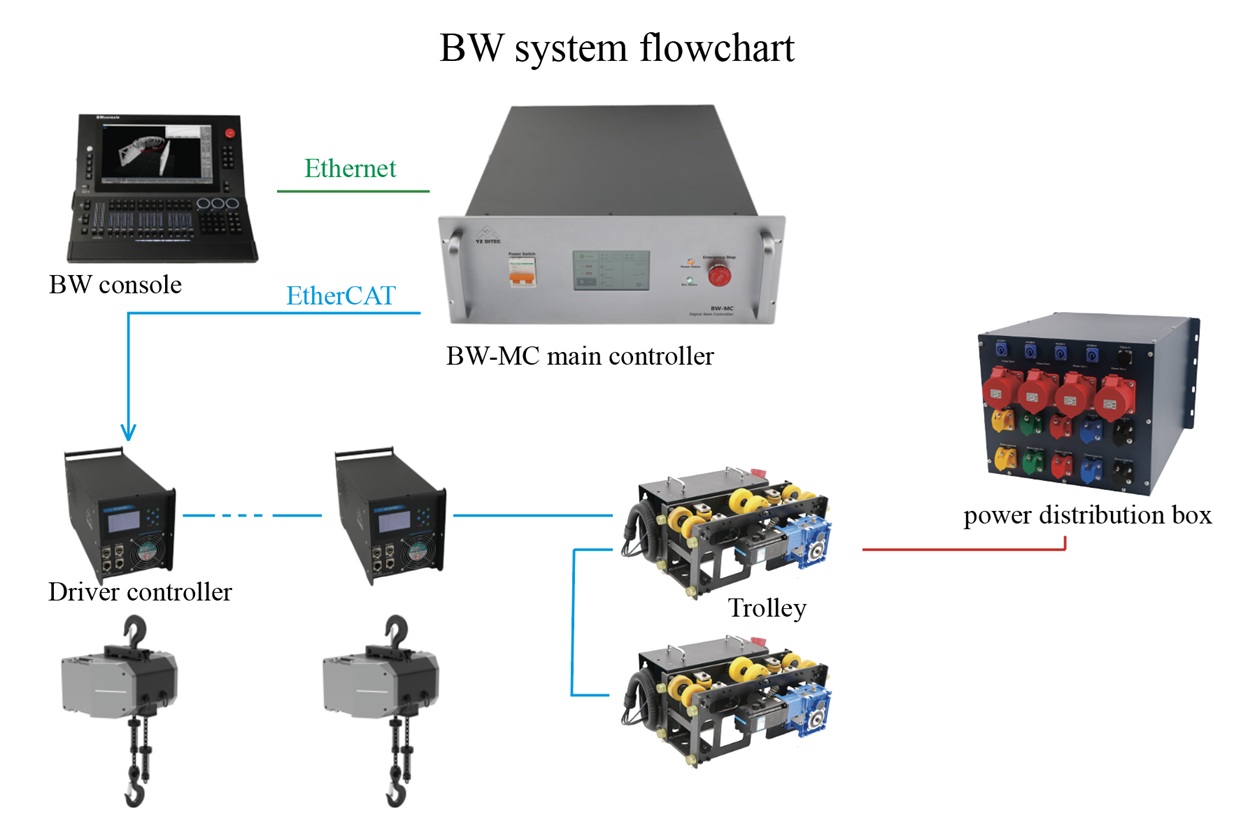

Developed by YZ DITEC, the BW-MC is the central control brain for professional stage machinery, combining:

✔ Multi-axis synchronous control (up to 256 axes)

✔ Sub-millimeter precision (±0.5mm positioning accuracy)

✔ Rental-optimized architecture (modular & scalable)

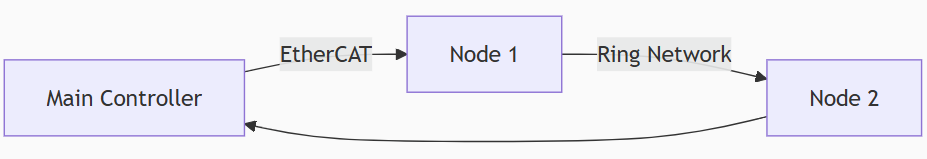

EtherCAT-based topology (1ms refresh rate)

Virtual axis mapping for complex trajectories

Motor health diagnostics

Temperature/load threshold alerts

Triple-redundant E-stop circuits (Cat.0/1/2)

Dynamic limit adjustment during operation

Capacity: 64/128-axis expandable configuration

Precision: ±0.1mm motion trajectory accuracy

Application: Perfect for large-scale stage machinery coordination

Response Time: <1ms

Reliability: Continuous operation even with single-point failures

Installation: 50% less cabling than traditional systems

| Function | Performance |

|---|---|

| Trajectory Planning | 7th-order polynomial interpolation |

| Position Control | 0.01mm resolution |

| Dynamic Adjustment | Real-time load compensation |

Parameters Tracked:

✓ Position

✓ Speed (RPM)

✓ Current (A)

✓ Temperature (°C)

Alert Thresholds: Customizable for each axis

Integrated Systems:

Motion control PLC

Power distribution

EtherCAT/DMX512/OSC communication

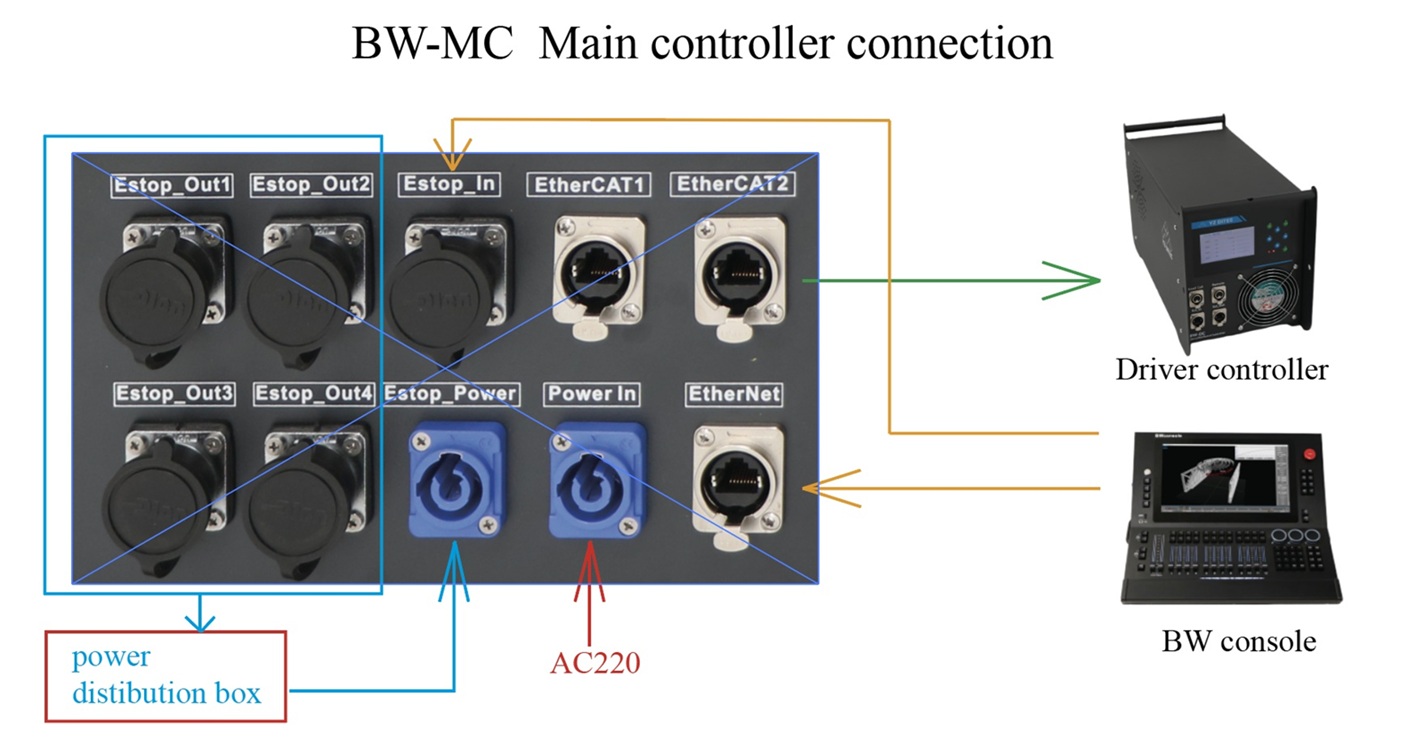

Benefit: 30% fewer connection points → Higher reliability

| Category | Specification |

|---|---|

| Power Input | AC100–240V; 50–60Hz |

| Input Current | 3A @110VAC, 1.5A @220VAC |

| Control Capacity | 64/128 selectable axes • 128-axis mode supports EtherCAT bus redundancy |

| Communication Interfaces | • EtherCAT ports x2 • Ethernet x1 • E-stop interfaces x2 • Power interface x1 • Status indicators x2 |

| Emergency Stop System | • Local E-stop • Expandable E-stop link • Supports Category 0 & 1 stops |

| Physical Specifications | • Dimensions: 482×542×177mm (W×H×D) • Operating Temp: 0℃~50℃ |

| Language Support | Chinese/English |

Tailored Development:

Custom firmware/software for unique stage requirements

Specialized motion profiles for complex performances

Venue-specific safety protocol integration

| Coverage | Details |

|---|---|

| Warranty Period | 12 months (extendable) |

| Technical Support | Lifetime remote diagnostics |

| Response Time | <4 hours for critical issues |

24/7 multilingual technical hotline

On-site service available (48-hour response for premium contracts)

Annual maintenance programs available