Project name: Talk Show & Friends

Client / Production: Tencent Video talk-show competition (Guests included Li Yuchun (singer), Chen Luyu (TV host), Da Zhangwei (singer), Luo Yonghao (entrepreneur and tech influencer), and Zhang Shaogang (TV host); 59 contestant groups on-site).

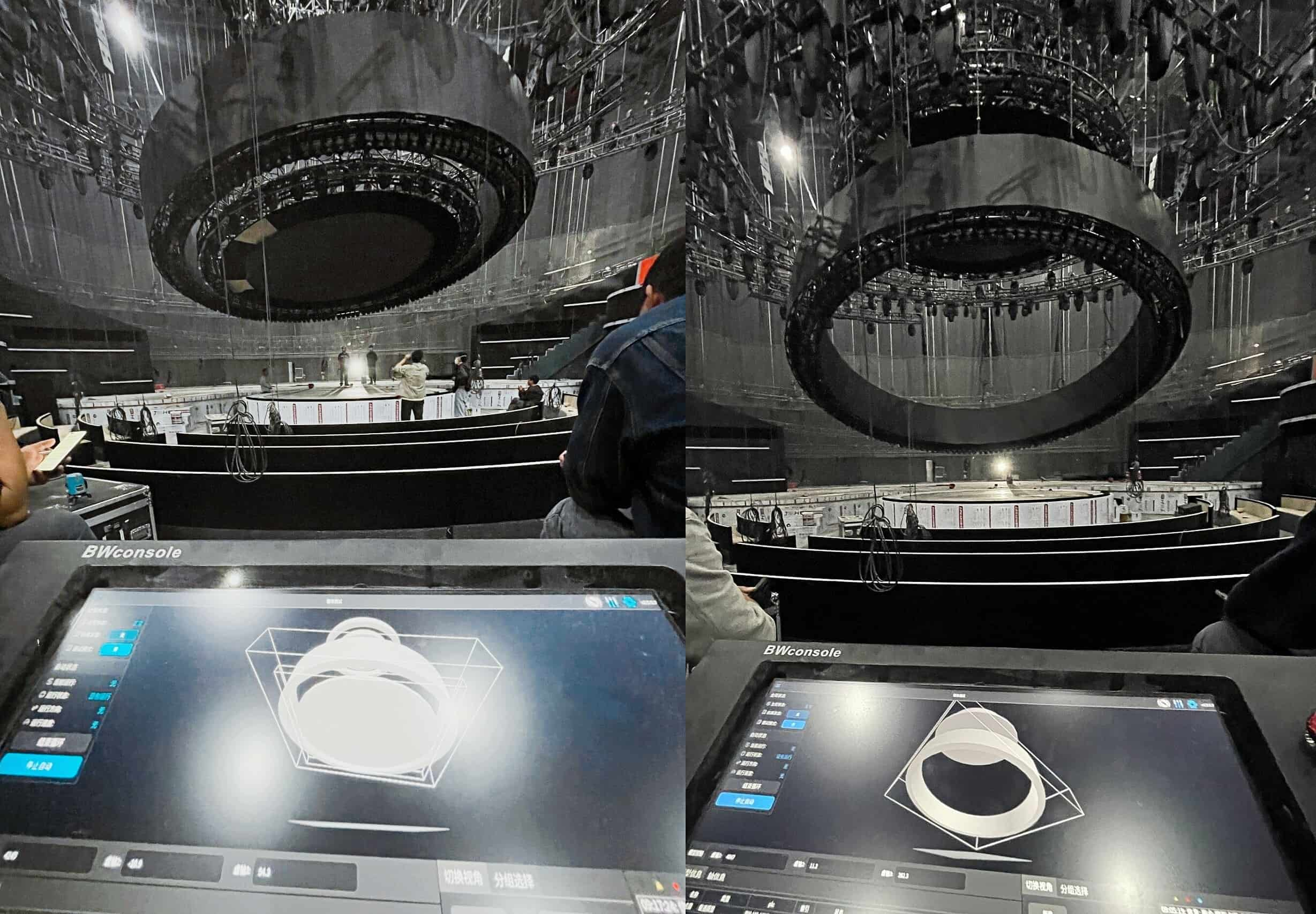

Scope delivered by YZDITEC: Full electromechanical design, manufacture and synchronized on-site control of the central stage mechanism (installed above center stage, also serving as support for lighting fixtures and LED background).

1. Background & Key Challenges

The creative brief required a mechanized, high-impact opening sequence driven by a large central ring. Technical and operational challenges included:

► Achieving large angular displacements through synchronized multi-point actuation of an oversized central ring, while balancing expressive motion with smooth, stable operation.

► Executing complex trajectories (arcs, spirals and multi-dimensional compound paths) with millimetre-level synchronization and seamless motion continuity across multiple actuators.

► Satisfying live broadcast-grade requirements for redundancy, repeatability and high reliability during simultaneous live and streamed transmission.

► Ensuring deterministic timing between mechanical motion and stage visuals (LED, lighting) for frame-accurate integration.

2. Our Solution — Executive Summary

YZDITEC delivered an end-to-end electromechanical and control package to meet these demands:

► Hoisting system: Deployed 37 × C1-series intelligent CNC chain hoists with servo drives operating as a synchronized cluster. Each hoist uses servo motors with absolute encoders to retain position after power loss and to provide high-integrity feedback.

► Real-time load balancing: Implemented closed-loop force equalization using motor feedback (torque/force) and internal hoist load measurements for continuous micro-adjustment, minimizing local overload risk.

► Control platform: Coordinated multi-hoist scheduling and trajectory planning under YZDITEC’s proprietary "Black Warrior" intelligent control console, enabling continuous, smooth execution of complex trajectories; built on the EtherCAT real-time fieldbus for high-frequency synchronization and real-time status monitoring.

► Validation & commissioning: Completed comprehensive factory performance and safety validation (including dynamic load and interruption response tests), followed by detailed on-site commissioning and acceptance.

► Standards & certification: TÜV Rheinland, BGV-C1, CE; compliant with EN 17206.

► Result: Smooth, visually compelling mechanical motion under complex trajectories and large-angle swinging motion, with millimetre-level synchronization and real-time load-balanced operation that balances aesthetic impact and operational safety.

Talk show on-site commissioning and acceptance

Factory performance and safety validation

3. Key Technical Highlights (for industry clients)

► Clustered synchronized architecture: 37 hoists act as a single coordinated system under “Black Warrior” control console, enabling multi-point linkage and unified trajectory following. Platform capacity: up to 128 control loops (axes) and management of 256 device models per master controller.

► Model-driven real-time control: “Black Warrior” control console maps logical models to physical devices (models store runtime parameters). During execution the model mirrors rigging state for online monitoring, collision detection and over-limit warnings.

► High-precision spatiotemporal control: Position command resolution 1 mm; programming time resolution 0.1 s; EtherCAT communication cycle 2 ms — ensuring broadcast-grade synchronization and stability.

► Offline 3D simulation & safety algorithms: Integrated Pando 3D simulation software supports offline programming with timeline- and spreadsheet-based motion editing, rehearsal, collision checks, intelligent over-limit alerts and automated correction, reducing on-site tuning time.

► Interfacing & show integration: Native DMX512 triggering, fiber-optic master links (>500 m), and wireless real-time operation with instant fault alarms via mobile, tablet, or PC — ensuring flexible and responsive system control.

► Preset motion library: Common motion presets (vertical lift, wave, ripple, spiral ascent, etc.) to accelerate programming and repeatability.

4. Safety & Quality Assurance

A three-layer protection strategy was implemented:

► Mechanical layer (physical redundancy): load cells, 4-point limit switches, dual brakes, overload protection, redundant primary/secondary suspension points, and G80 chains (SF12). Mechanical-level faults trigger mechanical braking or power cutoff.

► Software layer (logical safeguards): preset motion limits, Pando offline collision detection, over-limit detection & auto-correction, continuous monitoring and logging— ensuring all movements execute strictly within defined safety constraints.

► Control layer (operation & emergency response): “Black Warrior” control console provides emergency stop circuits (supporting Category 0 & 1 stops), real-time monitoring interface and hierarchical fault-alarm system for immediate intervention.

Implementation approach:

The control strategy incorporates real-time load monitoring for automatic fine-tuning and anomaly alerts. Each unit undergoes multiple rounds of performance and safety testing — including dynamic load tests and synchronized interruption response tests — prior to delivery. After on-site integration, standardized operation guidelines and training sessions are provided through detailed instruction materials and live demonstrations, ensuring the system’s traceability and reproducibility throughout touring operations.

5. On-stage Presentation & Audience Impact

► The oversized ring served as the show’s visual centerpiece—its synchronized multi-point swinging, combined with dynamic lighting and on-ring title displays that progressed with the show’s segments, acted as a live program indicator for the audience.

► Positioned centrally above the stage, the mechanism doubled as an LED and lighting carrier, integrating scenic motion with digital content.

► Mechanical motion was tightly choreographed with LED and lighting via DMX512 and console timelines, making the machinery an active element of storytelling.

► The result combined high visual impact with industrial-grade reliability suited for repeated live broadcasts and touring.

6. Client Value & Outcomes

► Delivered repeatable, stable dynamic staging that significantly elevated the show’s opening impact.

► Reduced operational risk and extended equipment life through real-time load balancing, high-margin component selection (SF12 chain) and a multi-layer safety architecture.

► Shortened on-site debugging and improved reproducibility via model-driven control and Pando simulation.

► Produced a replicable electromechanical & control blueprint for similar large-scale, multi-point touring installations.

7. Technical Snapshot (quick reference)

a) Hoisting system: 37 × C1 certified intelligent CNC chain hoists (servo drive; absolute encoder)

b) Certifications: TÜV Rheinland / BGV-C1 / CE / EN 17206

c) Control: “Black Warrior” control console (YZDITEC proprietary; 3D model-driven; EtherCAT)

d) System capacity: up to 128 control loops; manage up to 256 models (single master)

e) Precision & response: Position resolution 1 mm; time resolution 0.1 s; EtherCAT cycle 2 ms

f) Features: multi-point synchronized swinging; complex trajectory interpolation; real-time load micro-adjust; offline Pando 3D simulation & collision detection; DMX512 integration; fiber comms >500 m; wireless real-time monitoring & alarms; emergency stop (Category 0/1)

g) Testing: factory performance & safety validation; on-site commissioning and live validation (dynamic load and interruption-response tests)

8. Conclusion — Technology Empowering Performance

The Talk Show & Friends project demonstrates YZDITEC’s capabilities in large-scale CNC hoist cluster control and safety-centric engineering. By combining certified, high-margin components, a SIL3-equivalent control philosophy within “Black Warrior” console, and a robust three-tier safety architecture, we delivered a solution that preserves creative expression while minimizing risk—providing repeatable, broadcast-grade stage motion that production teams can rely on.

To see more of the live stage effects, please click the YouTube link below to watch the full video.